Details

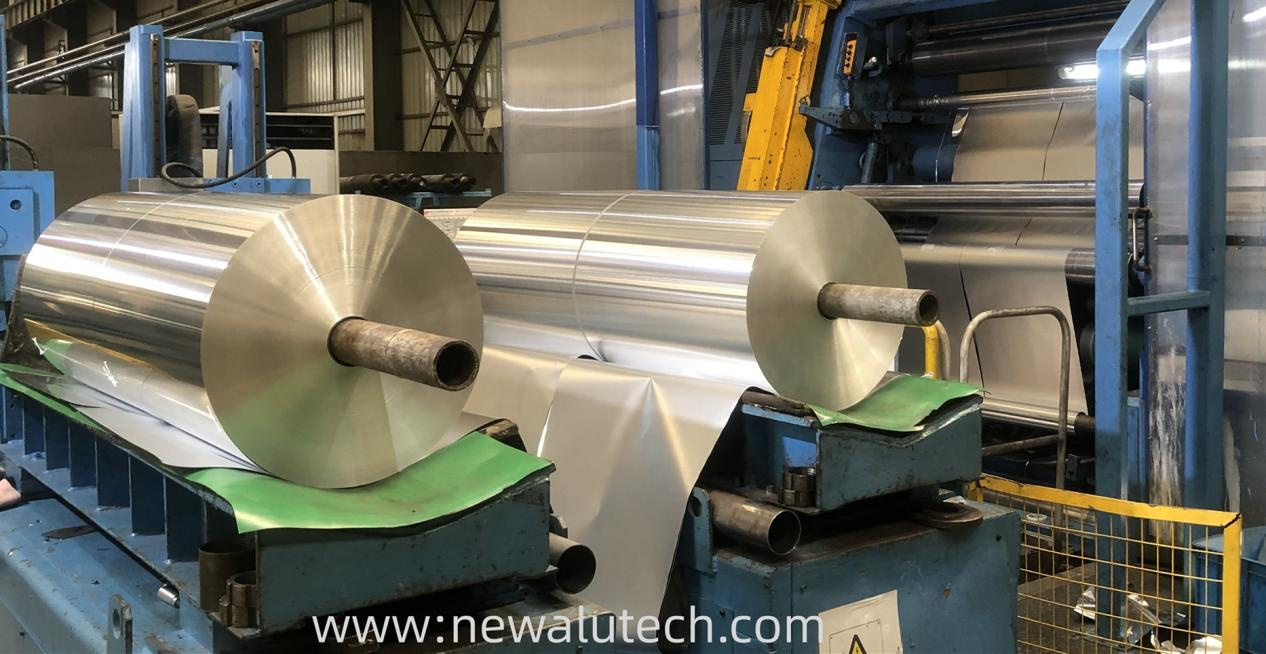

The Lithium Ion Battery Aluminum foil is become more and more popular in the new energy in the past 9 years all over the world ,especially in China and Europe. Lithium Ion Battery aluminum foil is used for the positive electrode in lithium-ion rechargeable battery.It asks for very high requirements for the surface .the usual alloy is 1060 ,1070 and 1235 . Zhejiang New Aluminum Tech Co Ltd is one of the leader for the battery aluminum foil in China . The battery foil produced by Zhejiang New Aluminum Technology is one of the base materials for new energy vehicle lithium batteries, which can effectively adjust the performance of power lithium batteries. The company’s battery foil customers cover CATL, BYD, Gotion High-Tech and other large Chinese lithium battery manufacturers.We also export to Japan and Europe for the LIB companies.

The Lithium Ion Battery Aluminum foil is become more and more popular in the new energy in the past 9 years all over the world ,especially in China and Europe. Lithium Ion Battery aluminum foil is used for the positive electrode in lithium-ion rechargeable battery.It asks for very high requirements for the surface .the usual alloy is 1060 ,1070 and 1235 . Zhejiang New Aluminum Tech Co Ltd is one of the leader for the battery aluminum foil in China . The battery foil produced by Zhejiang New Aluminum Technology is one of the base materials for new energy vehicle lithium batteries, which can effectively adjust the performance of power lithium batteries. The company’s battery foil customers cover CATL, BYD, Gotion High-Tech and other large Chinese lithium battery manufacturers.We also export to Japan and Europe for the LIB companies.Packing and Stuffing

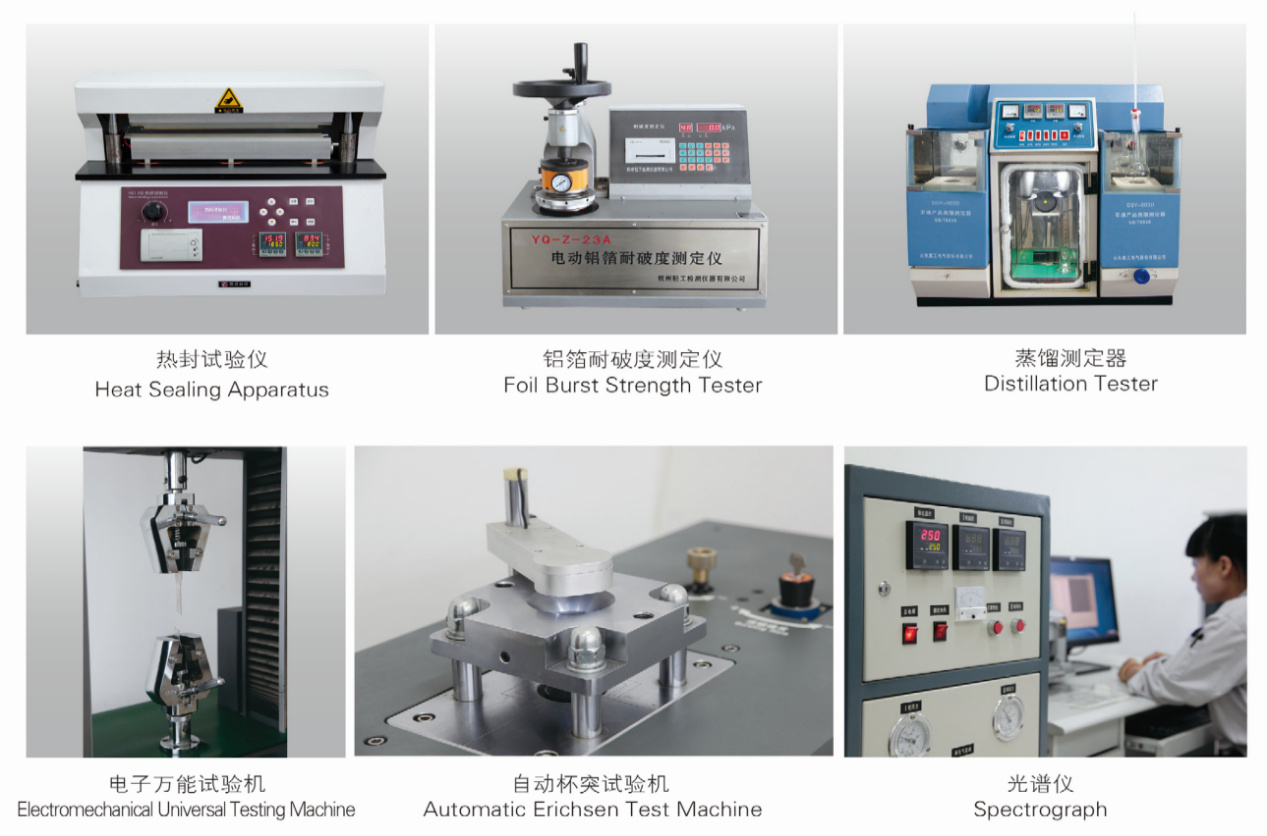

Quality Guarantee

The characteristics for the Battery aluminum foil : · Excels in foil flexibility Due to its flexibility, this foil is resistant to the expansion and contraction of battery at the time of charge/discharge. · Good in smoothness on either side The active material to provide the functionality of battery can be applied uniformly. · Small in foil thickness variation Due to its small thickness variation, the coating thickness variation of active material can be suppressed. To raise the output power, the HEV battery has a thinner active material layer than the commercial batteries. The smaller the foil thickness variation, the smaller can be made the thickness variation of the active material. This advantageous property of our product has been highly appreciated by every automotive battery manufacturers, and is often a decisive factor in accepting orders.| Name | Aluminum Foil For Lithium Ion Battery |

| Alloy-temper | 1060 1070 1235 O /H18 |

| Thickness | 0.01- 0.03mm (tolerance:±5%) |

| Width and tolerance | 300- 1200 mm (tolerance:± 1.0mm) |

| Weight | 200 - 500kg per roll coil (or customized) |

| Surface quality | Free of black spot, line mark, creases, clean and smooth, no corrosion stains, wrinkles, and fish tails. Surface quality has to beuniform and no chatter marks. |

| Core material | Steel / aluminum |

| Core ID | Ф76mm, Ф150mm (±0.5mm) |

| Packaging | Fumigation free wooden cases(keep us informed if any special requests) |

| Tensile Strength(Mpa) | 》190 MPa (according to thickness) |

| Elongation % | ≥2% |

| Wettability | A grade |

| Surface wetting tension | ≥32 dyne |

| Application | for battery case of new energy, mobile phone and digital products |

| Deliver time | within 20 days after getting the original LC or 30% deposit by TT |

| Item | Standard 1 | Standard 2 |

| hardness | H18 | H18 |

| width | Standard width ±1mm | Standard width ±1mm |

| Thickness | 0.016±0.002 mm | 0.012±0.002mm |

| areal density | 42~46g/ m2 | 30~34g/m2 |

| With transverse surface density uniformity | ≤0.003 g/ 40×40 mm | ≤0.003 g/ 40×40 mm |

| The same volume of vertical surface density uniformity | ≤0.03 g/ 400×40 mm | ≤0.03 g/ 400×40 mm |

| High temperature oxidation resistance (200°C*30min) | No oxidation | No oxidation |

| Connect no | <2 | <2 |

| Chemistry content(Al) | >99.45% | >99.45% |

| extensibility | <0.5% | <0.5% |

| Normal temperature Tensile strength kgf/mm2 | >180 | >140 |

| After 1200C baking 1h, Tensile strength kgf/mm2 | >160 | >120 |

| Coating performance | Aluminum foil with uniform tension on both sides, slurry coating uniformity | |

Recent advances in rolling and alloy manufacturing technologies have allowed us to develop uniformly thick, high-strength battery aluminum foil for lithium-ion cell and capacitor manufacturers. Ranging from 0.01-0.03mm in thickness, our standard and etched aluminum foils are produced in commercial quantities using high-performance aluminum alloys. For more information about our available products, please contact us . Whatsapp:0086 150 2440 2133 Email: newalu01@hotmail.com Zhejiang New Aluminium Technology Co.,Ltd www.newalutech.com www.newaluchina.com Professional Make Perfect ,Let's Do More Together !

Recent advances in rolling and alloy manufacturing technologies have allowed us to develop uniformly thick, high-strength battery aluminum foil for lithium-ion cell and capacitor manufacturers. Ranging from 0.01-0.03mm in thickness, our standard and etched aluminum foils are produced in commercial quantities using high-performance aluminum alloys. For more information about our available products, please contact us . Whatsapp:0086 150 2440 2133 Email: newalu01@hotmail.com Zhejiang New Aluminium Technology Co.,Ltd www.newalutech.com www.newaluchina.com Professional Make Perfect ,Let's Do More Together !