Details

We produce the aluminum foil from the ingot to aluminum coil by the Achenbach Foil Rolling Mill from Germany and Kampf Foil Slitter. The max width is 1800 mm and the Min thickness is 0.006 mm . With the help of high technology ,we can produce all kinds of aluminum coil with different standards as EN and control every step of production and retrospect all the raw material source . Our capacity is 6000 tons per month for the aluminum coil ,there are more than 4000 tons are export to all over the world . We only produce high quality with competitive price as well as good service .

We produce the aluminum foil from the ingot to aluminum coil by the Achenbach Foil Rolling Mill from Germany and Kampf Foil Slitter. The max width is 1800 mm and the Min thickness is 0.006 mm . With the help of high technology ,we can produce all kinds of aluminum coil with different standards as EN and control every step of production and retrospect all the raw material source . Our capacity is 6000 tons per month for the aluminum coil ,there are more than 4000 tons are export to all over the world . We only produce high quality with competitive price as well as good service .Parameter

Zhejiang New Aluminum Technology Co ltd produce the aluminum coil from the ingot, So we can control the quality from the source .Application

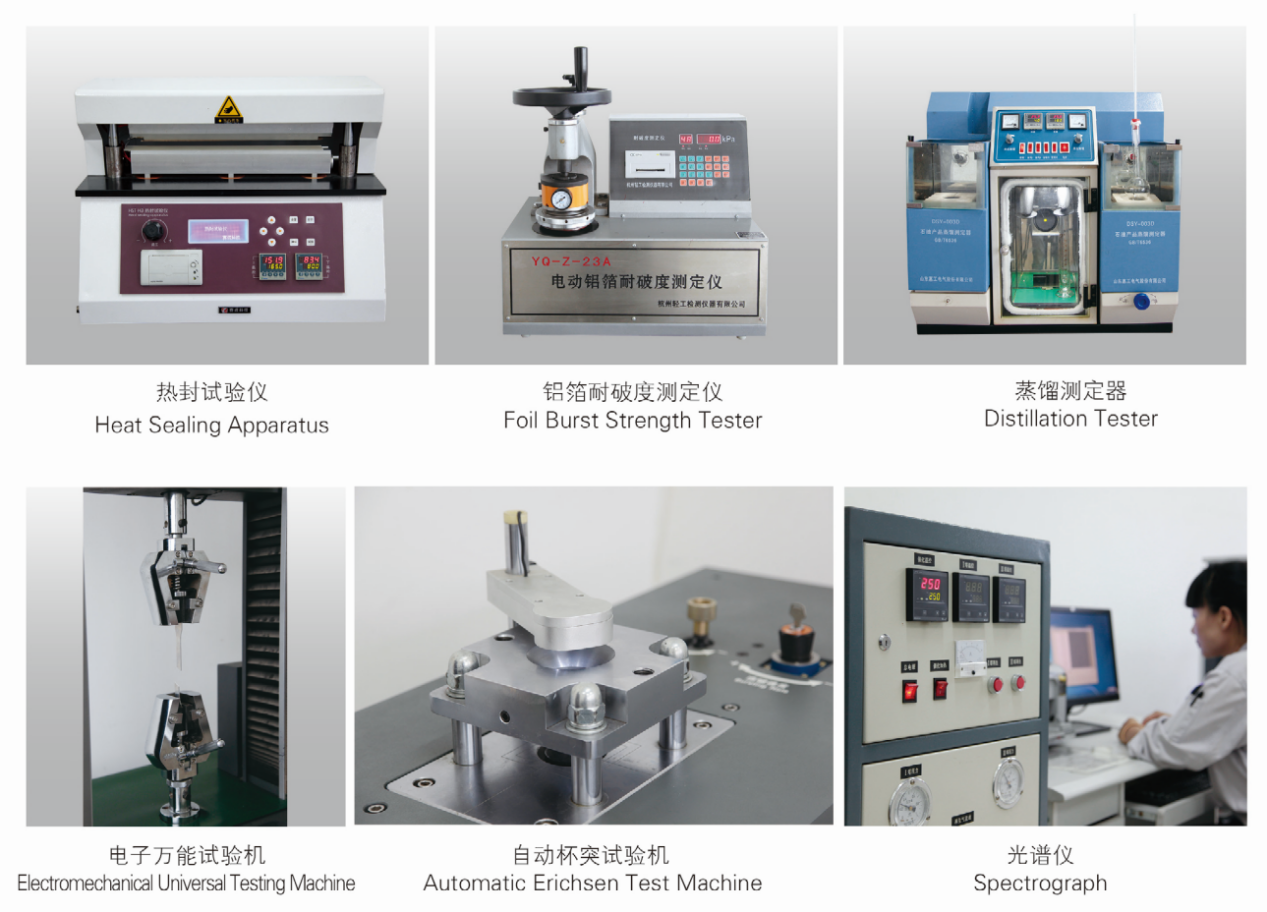

We have strictly quality control system from aluminium ingot to finish aluminium roll products, and test all products before packing,just in order to make double sure that only qualified product will be delivery to clients as we know even if little problem by us in our factory maybe lead to a big trouble for clients when they get .If customer need ,we can apply the SGS and BV inspection when producing or loading.Quality Guarantee

If you want more information and price ,please feel free to contact us in any time. Welcome to visit us .

| Name | Jumbo Roll Household Aluminum Foil |

| Alloy-temper | 8006-O, 8011-O |

| Thickness | 0.008mm(8micron) - 0.04mm (40micron) (tolerance:±5%) |

| Width and tolerance | 60- 1800 mm (tolerance:± 1.0mm) |

| Weight | 100 - 250kg per roll coil (or customized) |

| Surface | one side matte, one side bright or both side bright |

| Surface quality | Free of black spot, line mark, creases, clean and smooth, no corrosion stains, wrinkles, and fish tails. Surface quality has to be uniform and no chatter marks. |

| Core material | Steel / aluminum |

| Core ID | Ф76mm, Ф150mm (±0.5mm) |

| Packaging | Fumigation free wooden cases(keep us informed if any special requests) |

| Tensile Strength(Mpa) | 45-110MPa (according to thickness) |

| Elongation % | ≥1% |

| Wettability | A grade |

| Surface wetting tension | ≥32dyne |

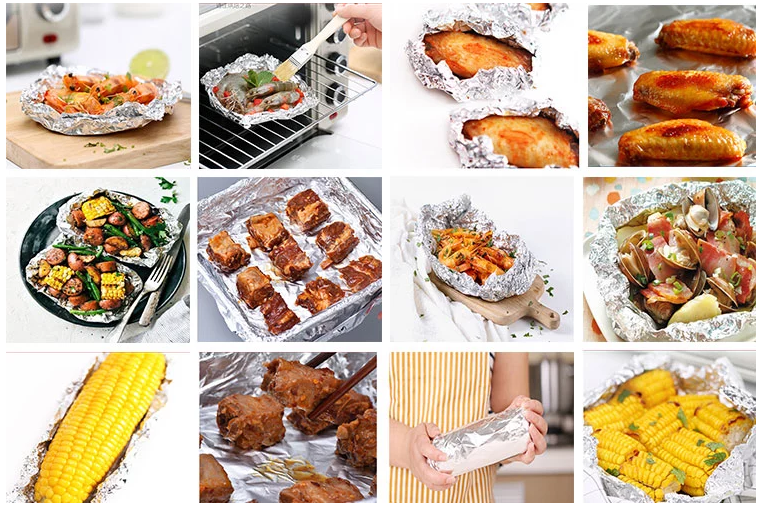

| Application | used in cooking, freezing, baking, and other food packaging |

| Deliver time | within 20 days after getting the original LC or 30% deposit by TT |

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others | Al |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | - | 0.1 | 0.08 | Rem |

| 8006 | 0.40 | 1.2-2.0 | 0.30 | 0.30-1.0 | 0.10 | 0.10 | - | - | Rem |